The Art of Refinement: A Comprehensive Guide to Jewelry Polishing Wheels

Related Articles: The Art of Refinement: A Comprehensive Guide to Jewelry Polishing Wheels

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Art of Refinement: A Comprehensive Guide to Jewelry Polishing Wheels. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Art of Refinement: A Comprehensive Guide to Jewelry Polishing Wheels

Jewelry polishing wheels, often referred to as buffing wheels, are essential tools in the jewelry-making and restoration process. These specialized wheels, crafted from various materials, play a crucial role in achieving a brilliant, lustrous finish on metal jewelry pieces. Their purpose is to remove imperfections, scratches, and tarnish, restoring the original beauty and shine of the metal. This comprehensive guide delves into the intricacies of jewelry polishing wheels, exploring their construction, types, applications, and the techniques employed for optimal results.

Understanding the Mechanics of Jewelry Polishing Wheels

The fundamental principle behind jewelry polishing wheels lies in their abrasive action. The surface of the wheel is typically composed of a material that, when rotated at high speeds, gently removes microscopic layers of metal, resulting in a smooth and polished finish. The type of abrasive used and the speed of rotation are key factors in determining the final outcome.

The Anatomy of a Jewelry Polishing Wheel

A typical jewelry polishing wheel comprises several components:

- The Wheel: This is the core of the polishing system, usually made of a durable material like felt, leather, or canvas. The wheel’s material and construction directly influence its polishing properties.

- The Mandrel: This is a metal rod that attaches the wheel to the polishing motor or lathe. The mandrel’s size and shape should be compatible with the chosen wheel and polishing equipment.

- The Abrasive: This is the key element that provides the polishing action. Abrasives are available in various forms, including compounds, pastes, and powders. The type of abrasive chosen depends on the metal being polished and the desired finish.

Types of Jewelry Polishing Wheels

The world of jewelry polishing wheels offers a diverse range of options, each tailored for specific applications and materials:

- Felt Wheels: These are widely used for polishing silver, gold, and platinum. Felt wheels are soft and pliable, making them ideal for achieving a high-gloss finish.

- Leather Wheels: Leather wheels are known for their durability and ability to handle harder metals like steel and brass. They are often used for removing scratches and achieving a satin finish.

- Canvas Wheels: Canvas wheels are a versatile option suitable for both polishing and buffing. They are typically used for removing heavier scratches and achieving a matte finish.

- Synthetic Wheels: Modern advancements have introduced synthetic wheels made from materials like nylon or silicone. These wheels offer excellent durability, resistance to heat, and a smooth polishing action.

Choosing the Right Jewelry Polishing Wheel

Selecting the appropriate polishing wheel is crucial for achieving the desired finish. Here are some key factors to consider:

- Metal Type: Different metals require different polishing techniques. Soft metals like silver and gold require gentler polishing than harder metals like steel and brass.

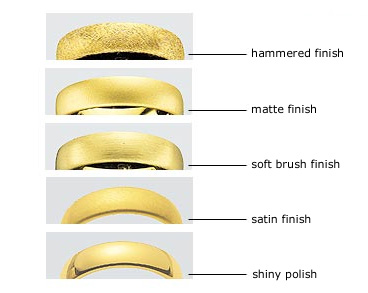

- Desired Finish: The desired finish – be it high gloss, satin, or matte – will dictate the choice of wheel and abrasive.

- Size and Shape: The size and shape of the wheel should be appropriate for the size and shape of the jewelry piece being polished.

The Importance of Abrasives

Abrasives are the heart of the polishing process. They are the agents that remove imperfections and create the desired finish. Abrasives are available in various forms, each with its own characteristics:

- Compounds: These are pre-mixed pastes or creams containing abrasive particles suspended in a binder. They are easy to use and are available in various grits for different polishing stages.

- Pastes: These are thicker, more concentrated versions of compounds. They are ideal for achieving a high-gloss finish and are often used for final polishing steps.

- Powders: Abrasive powders are available in various grits and are typically used for heavier polishing tasks. They are often mixed with water or oil to form a paste.

Techniques for Effective Jewelry Polishing

Polishing jewelry with a wheel is a delicate art that requires practice and precision. Here are some essential techniques to master:

- Preparation: Ensure the jewelry piece is clean and free of any debris. Use a cleaning solution appropriate for the metal type.

- Starting with a Coarse Grit: Begin with a coarser grit abrasive to remove deeper scratches and imperfections. Gradually progress to finer grits for a smoother, more polished finish.

- Applying Pressure: Apply gentle, even pressure to the wheel as you polish. Too much pressure can distort the metal or damage the wheel.

- Maintaining Speed: Maintain a consistent speed throughout the polishing process. Too much speed can generate heat, potentially damaging the metal.

- Cooling: Allow the jewelry piece to cool down periodically to prevent overheating.

Safety Precautions

Polishing jewelry with wheels can be a potentially hazardous activity. It is essential to prioritize safety throughout the process:

- Eye Protection: Wear safety glasses to protect your eyes from flying debris or abrasive particles.

- Gloves: Wear gloves to protect your hands from contact with abrasive materials.

- Ventilation: Ensure adequate ventilation to avoid inhaling abrasive dust or fumes.

- Machine Safety: Ensure the polishing machine is properly grounded and that all safety guards are in place.

FAQs about Jewelry Polishing Wheels

Q: What is the best polishing wheel for gold jewelry?

A: Felt wheels are generally preferred for polishing gold jewelry, as they offer a smooth, high-gloss finish. However, leather wheels can also be used for specific polishing tasks.

Q: How do I know which grit of abrasive to use?

A: Start with a coarser grit to remove deeper scratches and gradually progress to finer grits for a smoother finish. Refer to the abrasive manufacturer’s recommendations for specific grit selection.

Q: Can I use a polishing wheel on any metal?

A: While polishing wheels are effective on various metals, some metals are more sensitive to polishing than others. Always consult with a professional or refer to the metal’s specific polishing guidelines.

Q: How often should I replace a polishing wheel?

A: The lifespan of a polishing wheel depends on its usage and the type of abrasive used. When the wheel becomes worn or loses its effectiveness, it should be replaced.

Q: What are some common mistakes to avoid when polishing jewelry?

A: Common mistakes include applying excessive pressure, using the wrong abrasive, and neglecting to cool the jewelry piece.

Tips for Successful Jewelry Polishing

- Invest in Quality Tools: Use high-quality polishing wheels and abrasives for optimal results.

- Practice Patience: Jewelry polishing requires practice and patience. Start with simple pieces and gradually work your way up to more complex designs.

- Clean Thoroughly: Ensure the jewelry piece is thoroughly cleaned before and after polishing.

- Seek Professional Guidance: If you are unsure about any aspect of jewelry polishing, consult a professional jeweler or watchmaker.

Conclusion

Jewelry polishing wheels are indispensable tools for achieving a stunning, polished finish on metal jewelry. Understanding the different types of wheels, abrasives, and polishing techniques is crucial for achieving optimal results. By following the guidelines and safety precautions outlined in this guide, individuals can confidently enhance the beauty and brilliance of their jewelry creations. Remember, polishing jewelry is a skill that requires practice and patience. With dedication and the right tools, you can unlock the art of refining metal surfaces and bring out the true brilliance of your jewelry.

Closure

Thus, we hope this article has provided valuable insights into The Art of Refinement: A Comprehensive Guide to Jewelry Polishing Wheels. We appreciate your attention to our article. See you in our next article!