Mastering Precision: A Comprehensive Guide to Jewelry Tube Cutters

Related Articles: Mastering Precision: A Comprehensive Guide to Jewelry Tube Cutters

Introduction

With great pleasure, we will explore the intriguing topic related to Mastering Precision: A Comprehensive Guide to Jewelry Tube Cutters. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Mastering Precision: A Comprehensive Guide to Jewelry Tube Cutters

- 2 Introduction

- 3 Mastering Precision: A Comprehensive Guide to Jewelry Tube Cutters

- 3.1 Understanding the Jewelry Tube Cutter: A Precision Tool for Shaping Metal

- 3.2 Key Components of a Jewelry Tube Cutter:

- 3.3 Types of Jewelry Tube Cutters:

- 3.4 Benefits of Using a Jewelry Tube Cutter:

- 3.5 Selecting the Right Jewelry Tube Cutter:

- 3.6 Using a Jewelry Tube Cutter:

- 3.7 Tips for Using a Jewelry Tube Cutter:

- 3.8 Frequently Asked Questions about Jewelry Tube Cutters:

- 3.9 Conclusion:

- 4 Closure

Mastering Precision: A Comprehensive Guide to Jewelry Tube Cutters

In the meticulous world of jewelry making, precision reigns supreme. Every element, from the intricate design to the flawless finish, demands tools that deliver accuracy and control. Among these essential tools, the jewelry tube cutter stands out as a vital instrument for shaping and manipulating metal tubing, a ubiquitous material in jewelry crafting.

Understanding the Jewelry Tube Cutter: A Precision Tool for Shaping Metal

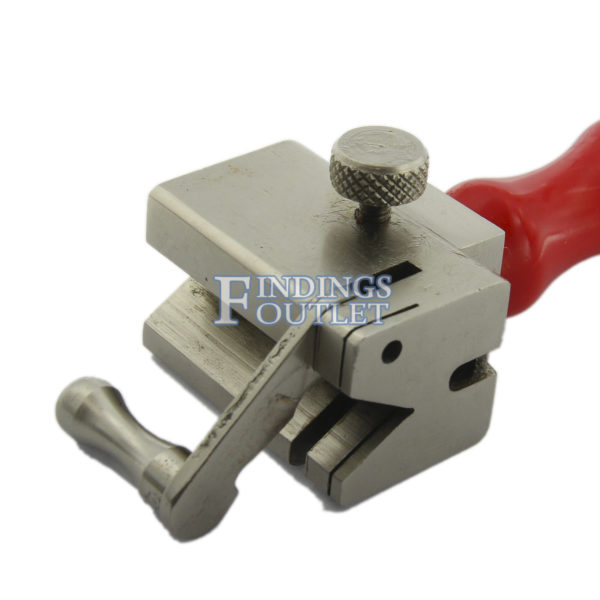

A jewelry tube cutter is a specialized tool designed to cleanly and accurately cut metal tubing, primarily used in jewelry making. It operates on a principle similar to that of a pipe cutter, employing a rotating wheel to score the metal tubing, creating a precise cut. The cutter’s design allows for controlled pressure application, ensuring clean, burr-free cuts that are essential for creating seamless connections and intricate designs.

Key Components of a Jewelry Tube Cutter:

1. Cutting Wheel: The heart of the cutter, the cutting wheel is typically made of hardened steel or tungsten carbide, ensuring durability and sharpness. The wheel’s sharpness is critical for achieving a clean, precise cut without deforming the metal tubing.

2. Cutting Head: The cutting head houses the cutting wheel and provides a secure platform for the tubing during the cutting process. It often features a mechanism to adjust the cutting wheel’s position, allowing for precise depth control.

3. Handle: The handle provides leverage and control during the cutting process. It is typically designed for ergonomic comfort, allowing for prolonged use without fatigue.

4. Adjustment Mechanism: This mechanism allows for precise adjustment of the cutting wheel’s position, ensuring consistent and accurate cuts.

5. Tube Support: Some jewelry tube cutters feature a tube support, which helps to stabilize the tubing during the cutting process, reducing the risk of slippage and ensuring a straight cut.

Types of Jewelry Tube Cutters:

1. Manual Jewelry Tube Cutters: These cutters are operated by hand, requiring manual pressure application to rotate the cutting wheel. They are typically more affordable and portable, making them suitable for smaller-scale jewelry making projects.

2. Lever-Action Jewelry Tube Cutters: These cutters utilize a lever mechanism to amplify the force applied to the cutting wheel, making cutting larger or thicker tubing easier. They offer more leverage and control compared to manual cutters.

3. Bench-Mounted Jewelry Tube Cutters: Designed for professional use, bench-mounted cutters provide a stable platform for cutting, ensuring greater accuracy and precision. They are typically equipped with a vise-like mechanism for securing the tubing, allowing for hands-free operation.

Benefits of Using a Jewelry Tube Cutter:

1. Precise Cuts: Jewelry tube cutters excel at producing clean, burr-free cuts, essential for creating seamless connections and intricate designs.

2. Versatility: They can handle a wide range of metal tubing sizes and materials, including silver, gold, copper, and brass.

3. Control and Accuracy: The adjustable cutting wheel and leverage mechanism allow for precise control over the cutting depth, ensuring consistent and accurate cuts.

4. Efficiency: Compared to other cutting methods like sawing or using a hacksaw, jewelry tube cutters offer a faster and more efficient way to cut metal tubing.

5. Durability: Well-made jewelry tube cutters are built to last, providing years of reliable service.

Selecting the Right Jewelry Tube Cutter:

Choosing the appropriate jewelry tube cutter depends on the specific needs of the project and the user’s experience level. Here are some factors to consider:

1. Tube Size and Material: The cutter’s capacity should accommodate the size and material of the tubing you intend to cut.

2. Cutting Depth: Consider the required cutting depth for your project and choose a cutter with an adjustable cutting wheel to accommodate your needs.

3. Leverage and Control: For larger or thicker tubing, a lever-action or bench-mounted cutter may be more suitable.

4. Budget: Manual cutters are typically more affordable, while lever-action and bench-mounted cutters come with a higher price tag.

5. Experience Level: Beginners might find a manual cutter easier to use, while experienced jewelers may opt for more advanced models.

Using a Jewelry Tube Cutter:

1. Prepare the Tubing: Ensure the tubing is clean and free of any debris that could interfere with the cutting process.

2. Secure the Tubing: Place the tubing securely in the cutter’s jaws or support mechanism.

3. Adjust the Cutting Wheel: Position the cutting wheel to the desired depth.

4. Apply Pressure: Rotate the cutting wheel using the handle or lever, applying consistent pressure to score the metal.

5. Complete the Cut: Continue rotating the wheel until the tubing is fully cut.

6. Deburr: After cutting, use a deburring tool to remove any sharp edges or burrs from the cut ends.

Tips for Using a Jewelry Tube Cutter:

- Use a cutting oil: Applying a cutting oil to the cutting wheel and tubing reduces friction and improves the cutting process.

- Avoid excessive pressure: Applying too much pressure can deform the tubing or damage the cutting wheel.

- Keep the cutting wheel sharp: A sharp cutting wheel ensures clean, precise cuts. Replace the wheel when it becomes dull.

- Clean the cutter regularly: Remove any debris or metal shavings from the cutter to maintain its performance.

Frequently Asked Questions about Jewelry Tube Cutters:

Q: Can I use a jewelry tube cutter for other materials besides metal tubing?

A: While jewelry tube cutters are primarily designed for metal tubing, they can also be used for cutting other materials like plastic or rubber tubing, depending on the material’s hardness and the cutter’s capacity.

Q: What is the difference between a jewelry tube cutter and a pipe cutter?

A: Both tools function on similar principles, but jewelry tube cutters are specifically designed for smaller tubing sizes and materials commonly used in jewelry making. They often feature finer cutting wheels and more precise adjustment mechanisms.

Q: How do I know when to replace the cutting wheel?

A: When the cutting wheel becomes dull or chipped, it will start to produce uneven or rough cuts. Replace the wheel when it no longer produces clean, precise cuts.

Q: What are some common mistakes to avoid when using a jewelry tube cutter?

A: Common mistakes include applying excessive pressure, using a dull cutting wheel, not cleaning the cutter regularly, and not using a cutting oil.

Q: Can I use a jewelry tube cutter for cutting wire?

A: While jewelry tube cutters are designed for cutting tubing, they can sometimes be used for cutting wire, depending on the wire’s diameter and the cutter’s capacity. However, specialized wire cutters are typically more suitable for this purpose.

Conclusion:

A jewelry tube cutter is an indispensable tool for any jewelry maker, offering precision, versatility, and efficiency in cutting metal tubing. By understanding the tool’s components, types, benefits, and proper usage techniques, jewelers can harness the power of this essential instrument to create intricate and stunning jewelry pieces. Whether you are a seasoned professional or a budding enthusiast, investing in a quality jewelry tube cutter will undoubtedly enhance your jewelry-making capabilities and elevate your craft to new heights.

Closure

Thus, we hope this article has provided valuable insights into Mastering Precision: A Comprehensive Guide to Jewelry Tube Cutters. We appreciate your attention to our article. See you in our next article!